Pneumatic cylinders - easily configurable

At Fluid24 you can choose from many different cylinders and actuators in the field of pneumatics. Very popular are for example the products of the series M or KD of the manufacturer Univer. In addition, there are many articles from other well-known brands such as SMC Pneumatic or FESTO.

- Univer - Serie W Short stroke cylinder - Ø 12 ÷ 100 mm Profile tube with new design, piston rod made of stainless steel, DW standard version, Ø40, 50 SKU:

W1000400050Special Price $ 70.73 Regular Price $ 94.30 Discount 25% - Univer series RP compact cylinder UNITOP - Ø 16 ÷ 63 mm, chrome - plated steel piston rod with internal thread, DW standard version, Ø32, 30 SKU:

RP2000320030Special Price $ 62.39 Regular Price $ 83.18 Discount 25% - Univer - Serie KL Pneumatic cylinder Cylinder ISO 15552 - CLEAN PROFILE, chrome plated steel piston rod, DW standard version, Ø32, 25, magnetic version standard SKU:

KL2000320025MSpecial Price $ 65.73 Regular Price $ 87.63 Discount 25% -

- Univer - Serie KL Pneumatic cylinder Cylinder ISO 15552 - CLEAN PROFILE SKU:

UNIVER-KLSpecial Price $ 65.73 Regular Price $ 87.63 Discount 25% -

- SMC Pneumatic - MXSL, Compact Slide, Double Acting, Cross Roller, Symmetrical SKU:

SMC-MXSL$ 327.76 -

- SMC Pneumatics - C (D) QSY, air cylinder, smooth, smooth running, double acting SKU:

SMC-CQSY-D$ 53.75 -

-

-

-

-

- SMC Pneumatic - M (D) BZ, pneumatic cylinder, double acting, standard piston rod SKU:

SMC-M$ 299.19 -

- SMC Pneumatic - C (D) UW, Miniature Cylinder for Direct Mounting, Through Piston Rod SKU:

SMC-CUW-D$ 73.24 - SMC Pneumatic - C (D) VHF, cylinder for direct mounting, anti-rotation, continuous piston rod SKU:

SMC-CUKW-D$ 94.29 - SMC Pneumatic - C (D) UK, cylinder for direct mounting, anti-rotation, long stroke SKU:

SMC-CUK-D$ 87.54 -

- SMC Pneumatic - C (D) UA, cylinder for direct mounting with pneumatic damping SKU:

SMC-CU-A$ 108.92 -

- SMC Pneumatic - C (D) QSX, slow speed compact cylinder, double acting, standard piston rod SKU:

SMC-CQSX-D$ 39.52 - SMC Pneumatics - C (D) QS, compact cylinder, double acting, standard piston rod, high shear load SKU:

SMC-CQSS-D$ 35.06 - SMC Pneumatics - C (D) QS, compact cylinder, double acting, standard piston rod SKU:

SMC-CQS-D$ 28.90 - SMC Pneumatic - C (D) NS, Cylinder with Locking Unit, double acting, standard piston rod SKU:

SMC-CNS-D$ 2,275.53 - SMC Pneumatic - C (D) NG, Cylinder with Locking Unit, double acting, standard piston rod SKU:

SMC-CNG-D$ 385.00

These advantages are provided by pneumatic drives

With pneumatic systems, you benefit from the ability to easily set the speed of a cylinder and the force it exerts over the pressure level. You can specify this with flow restrictors for each individual drive and, if necessary, continuously adjust them. Another advantage is that no power is required to hold an item. This can significantly reduce the energy required. Although the energy density is lower in pneumatic drives than in hydraulic systems, it is usually much higher than when using electrical components. Therefore, even small cylinders can develop a relatively high force. If you think about setting up an automated production facility in your facility, the cost factor certainly plays an important role. The pneumatics can score as well. The drives are quite simple and therefore relatively cheap. So you benefit from low investment costs.

The advantages of pneumatic drive systems at a glance:

- Stepless adjustment of power and speed

- High power despite small size

- Leakage does not cause any environmental damage

- Simple construction ensures low acquisition costs

- No separate cooling necessary

- No power is required to hold the workpieces

- High working speed

Cylinders in many different sizes: from standard cylinders to short-stroke cylinders

If you need pneumatic drives for your machines and equipment, then size plays an important role. Frequently, for example, an ISO cylinder 15552 is used. This model complies with the ISO standard and has a fixed size. Therefore, the ISO Cylinder 15552 is well compatible with other components and easier to install. Especially with firmly standardized pneumatic systems, these drives therefore offer a clear advantage. However, the ISO cylinder 15552 is too big for some applications. A solution would be in this case the micro-cylinder ISO 6432. It is also standardized, but has much smaller dimensions. Therefore, a micro cylinder ISO 6432 is always suitable when there is little space for installation. In addition to the ISO 6432 micro cylinder, there are many other small cylinders and compact cylinders that are not standardized. The different sizes may make the construction a bit more difficult. However, they naturally offer the advantage that you can choose from a large number of sizes for the compact cylinders and small cylinders and also find suitable drives for different applications. Even smaller than the previous models are usually Kurzhubzylinder. This allows you to generate a high force even in the smallest space. With fluid24, you can choose from a large number of small cylinders, compact cylinders and short-stroke cylinders, which ensure reliable power transmission even in small pneumatic machines.

Telescopic cylinders - up to 60% shorter dimensions compared to classic pneumatic cylinders

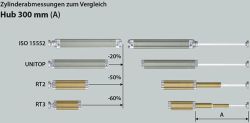

A highlight of the UNIVER product range are the space-saving RT telescopic cylinders of RT2 (2-stage Ø 25 ÷ 63 mm) and RT3 (3-stage Ø 40 ÷ 63 mm) which are used in industrial production. These are in-house developments from UNIVER. The requirements of the industrial companies for pneumatic cylinders are the most efficient use of available resources. For special production with limited space, a higher design effort may be necessary. Standard cylinders can no longer be used here and customer-specific products are reflected in the price. Here comes a telescopic cylinder to the train, which offers a space-saving alternative to classic pneumatic cylinders at fair prices.

The following features distinguish our telescopic cylinders:

- Advanced design and technology

- Industrialized components and high-quality technology

- Reduced dimensions with up to 60% compared to a classic cylinder

- As standard with anti-rotation octagonal cylinder tube

Other differences in the design

Drives in the field of Pneumatik differ not only in their size, but also in many other details. Often they are in the form of round cylinders, but there are also models with a square cross section available. Of course, you can also buy piston rod cylinders and rodless cylinders. Piston rod cylinders are the normal case: Here, a small rod transmits the force. For some applications, but rather rodless cylinders are recommended. These have the advantage that they are rather insensitive to a laterally acting force in comparison. For many round cylinders, there is only one connection for the compressed air - they are labeled with the keyword single-acting, because the force only acts in one direction. However, there are also double-acting models in the range. These provide two separate connections for the compressed air, with the help of which you can move the piston in both directions under force. Whether you need a piston rod cylinder, rodless cylinders, round cylinders or a completely different model - fluid24 has a wide range of options to help you find a suitable product for your projects. And if your system needs to be overhauled, of course, there are also the appropriate maintenance units.

![SMC Pneumatics - Electronic 3-Wire Signal Generator [D-M9]](https://media.fluid24.eu/catalog/product/cache/936e181fb0a42c2811493b70a8afb8e7/7/6/7695_pim.jpg)