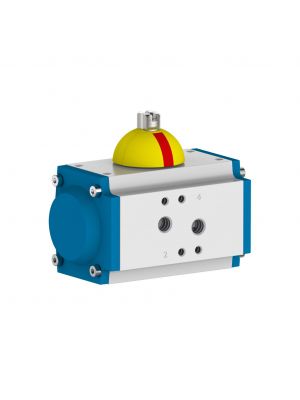

Pneumatic rotary actuators

We supply a large selection of different housing sizes for double-acting actuators (GTD), as well as single-acting versions (GTE) with spring return. In addition to the standard temperature range, the high temperature range up to 160 °C can also be configured in our shop.

Pneumatic actuator- configurator

Our configurator supports you in the selection of a suitable pneumatic drive type for your ball valve or flap.

GT series pneumatic actuators

The sophisticated product design, material specifications and manufacturing precision are just a few of the outstanding properties of these drives. The GT Series is designed for long-term, efficient performance with minimal maintenance.

Accessories for pneumatic rotary actuators

The attachment of accessories corresponds to the NAMUR specifications, the valve attachment sizes correspond to the ISO 5211 standard. We are also happy to supply suitable accessories such as position indicators and valve technology.

Assembly configurations pneumatic actuators

The graphics below show the relative orientation of the piston and pinion for each configuration, as viewed from the top side of the actuator. In the description that fallow, that perspective is assumed. Pinion rotation is indicated for each as clockwise (CW) or counter-clockwise (CCW).

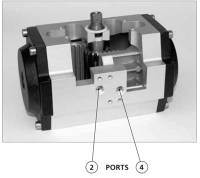

Pressure at Port 2

Port 2 is connected to the inboard side of the pistons. Pressurising port 2 will force the pistons out until they reach the travel stops. The direction of pinion rotation is determined by the assembly configuration of the actuator. Venting is through port 4.

Pressure at Port 4

Port 4 is connected to the outboard side of the pistons. Pressurising port 4 will force the pistons in until they reach the travel stops (if the actuator is equipped as they’re optional). The direction of the pinion rotation is determined by the assembly configuration. Venting is through port 2.

Double-acting pneumatic actuators

With this type of actuators, pressure is applied to the outer chambers of channel 4 and the pistons are compressed. The force is transmitted to the pinion, which moves to the home position. When pressure is applied to channel 2, the pistons are pushed apart and the pinion moves to the 90° position. The end position can be adjusted to -5 ° to + 5 ° using the adjusting screws of the stroke setting. On request, the drives can also be supplied with end position adjustment on both sides.

Single-acting pneumatic actuators

The single-acting actuators are available in the versions spring-force closing (Fail-Safe-Close) and spring-force opening (Fail-Safe-Open). The springs press the actuator back to its basic position when it is vented. Depending on the drive, the number of springs can be expanded from 2 pieces to up to 16 pieces, whereby the torques can be adjusted within the drive size and the available pneumatic pressure on the ball valve or the flap.

Information about the assembly variants

Note that on spring-return actuators, as with double-acting, pressurising port 2 will move the pistons out. When port 2 is depressurised, spring force will move the pistons in. Venting is through pot 4. Port 4 is not to be pressurised on spring-return actuators.